Then:

Now:

There’s a workplace revolution happening now from manufacturing plants to offices. A 2013 report from the Associated Press noted the damage to white-collar jobs:

In the U.S., more than 1.1 million secretaries vanished from the job market between 2000 and 2010, their job security shattered by software that lets bosses field calls themselves and arrange their own meetings and trips. Over the same period, the number of telephone operators plunged by 64 percent, word processors and typists by 63 percent, travel agents by 46 percent and bookkeepers by 26 percent, according to Labor Department statistics.And people wonder why the recession’s recovery has been jobless. It’s death by a thousand cuts.

Productivity has gone up while employment has decreased in the past 15 years. That fact alone should be a big hint about the effects of robots, computers and automation.

America certainly doesn’t need millions of low-skilled immigrant workers invading the job market, yet Washington acts as if labor needs are the same as 50 years ago. A 2013 Oxford University study (“The Future of Employment: How Susceptible Are Jobs to Computerisation?”) concluded that “about 47 percent of total US employment is at risk” to be replaced by smart machines.

America therefore needs ZERO immigrants to fill jobs. Enlarging the angry jobless underclass is unwise, to say the least.

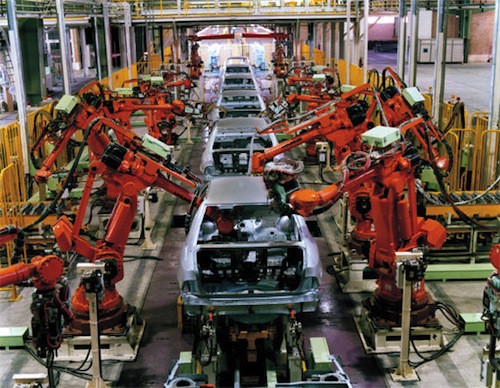

The businesses that produce industrial robots have been pushing forward, and smart machines have gotten cheaper and as a result are a viable alternative to humans.

More robots coming to U.S. factories, USA Today, February 9, 2015Manufacturers will significantly accelerate their use of robots in U.S. factories over the next decade as they become cheaper and perform more tasks, constraining payroll growth, according to a study out Tuesday.

The development is expected to dramatically boost productivity and slow the long-standing migration of factories across the globe to take advantage of low-cost labor, says the Boston Consulting Group report.

“Advanced robotics are changing the calculus of manufacturing,” says Harold Sirkin, a senior partner at the research firm.

A handful of nations, including the U.S. and China, are poised to reap the biggest benefits of the automation wave.

About 1.2 million additional advanced robots are expected to be deployed in the U.S. by 2025, BCG says. Four industries will lead the shift — computer and electronics products; electrical equipment and appliances; transportation; and machinery — largely because more of their tasks can be automated and they deliver the biggest cost savings.

About 10% of all manufacturing functions are automated, a share that will rise to nearly 25% in a decade as robotic vision sensors and gripping systems improve, the research firm says.

Meanwhile, costs are tumbling. The cost to purchase and start up an advanced robotic spot welder has plunged from $182,000 in 2005 to $133,000 in 2014, with the price forecast to drop another 22% by 2025.

That’s prodding manufacturers to replace workers. BCG says manufacturers tend to ratchet up their robotics investment when they realize at least a 15% cost savings compared with employing a worker. In electronics manufacturing, it already costs just $4 an hour to use a robot for a routine assembly task vs. $24 for an average worker.

Within two years, the number of advanced industrial robots in the U.S. will begin to grow by 10% a year, up from current annual growth of 2% to 3%, the study says.

The impact on U.S. factory workers is mixed.

Replacing employees with robots is projected to result in a manufacturing workforce that’s 22% — or a few million workers — smaller by 2025 than it otherwise would have been. But factory payrolls are still expected to rise because of an expanding economy and the growing tendency of manufacturers to move some production back to the U.S. from overseas — a trend known as reshoring, Sirkin says.

Indeed, the spread of robotics itself should make the U.S. more productive than many other countries, creating more jobs. BCG estimates reshoring will add 2.5 million to 5 million factory jobs in the U.S. by 2020. Many low-skills jobs, however, will be eliminated while higher-skill positions, such as operating and maintaining robots, are expected to grow.

The U.S. is among six countries that the research firm characterizes as “fast” adopters of advanced robotics, including China, Canada, Japan, Russia and the United Kingdom. But it says several countries will be even more aggressive — Indonesia, South Korea, Taiwan and Thailand.

The U.S. is expected to be far ahead of a larger number of slower adopters, such as France, Italy, Belgium and Brazil.

The surge in robotics will spawn smaller factories that can easily replicate assembly systems to serve local markets with customized products, the report says.